VPE has been providing contract manufacturing services since 1976. As a result, we manufacture components, subassemblies, and complete products for mission-critical aerospace, semiconductor, as well as medical applications. In addition, we specialize in the manufacturing of heat exchangers and cold plates. Furthermore, VPE combines expertise in materials science with extensive manufacturing experience to produce high volumes, maintain quality control, as well as assure on-time delivery.

Manufacturing Services – Capabilities

Our contract manufacturing services range from providing specific process or assembly tasks using customer-supplied parts to supplying production quantities of quality turnkey assemblies. Moreover, by serving as the prime contractor, we control the factors critical to manufacturing success.

- Metallurgical expertise for both R&D as well as production

- Highly efficient use of R&D as well as prototyping budgets

- Problem-solving for product design as well as production issues

- Turnkey production from drawings and specifications

- Turnkey product design, prototyping, and production

- One-off to volume production

- Specific process or assembly tasks

- Processes, parts, assemblies, as well as complete products

- Production-oriented for efficiency, low costs, as well as high quality

- High, medium, as well as low-volume production and fabrication

- Design and set up of production line with all tooling

- Production equipment development

- Material and subcontractor sourcing, qualifying, as well as supervision

- Well-qualified materials suppliers and subcontractors

- Advanced testing and analysis equipment

- AS9100, ISO 9001, plus customer-specific QA standards

AS9100 Certified. ITAR Registered.

VPE has extensive in-house capabilities for quality assurance as well as testing and analysis. Furthermore, company philosophy demands that every VPE product and service exceed compliance standards. As a result, VPE has a proud history of meeting and acquiring the quality certification demands of the market.

VPE’s extensive in-house capabilities meet many exacting certification requirements specific to applications or customers e.g.:

- Medical implants

- Aerospace

- Nuclear

- Defense

- Electronics

Manufacturing Services – Project Examples

VPE has been the manufacturer on the following projects e.g.:

- Aerojet Rocketdyne: reactive metal thermal processing

- Schilling: robotic assemblies for submarines used in the offshore oil industry

- NASA: Space Exploration as well as Lander programs

- Major aerospace contractor: engine fire sensors

- Major medical device corporation: ceramic to metal heater assemblies

- Fortune 10 corporation: Homeland Security assemblies

- Applied Materials: electrostatic particle accelerator tubes.

- Isolate Extraction Systems: Co2 extraction heat exchangers

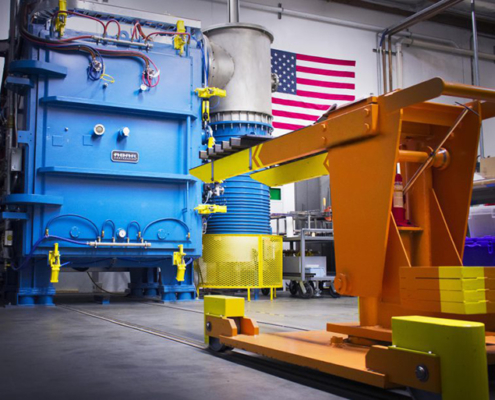

Equipment & Facilities

VPE provides over 150,000 square feet of design, lab, manufacturing, as well as quality assurance space for your contract manufacturing program.

- Vacuum brazing furnaces

- Aluminum vacuum brazing furnaces

- Hydrogen furnaces

- Thin film coating systems

- Induction & infrared braze systems

- Diffusion bonding furnaces

- Hot pressing furnaces

- The world’s largest vacuum hot press

- Machine shop

- Quality assurance facility

- Coordinate measuring machines (CMMs)

- Laboratories – cleanroom as well as clean environment

- Welding cells

- Cleaning lines

- Assembly lines

- Materials testing & analysis lab

- & more!

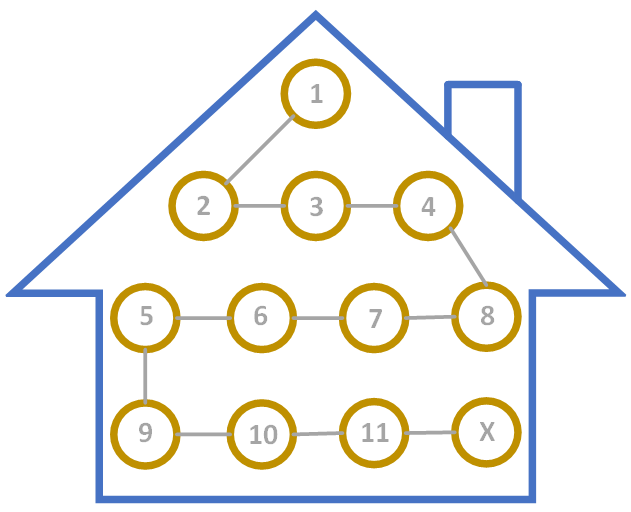

In-House Manufacturing: From Start to Finish

Extensive manufacturing capabilities allow the VPE manufacturing process to be done nearly entirely in-house. To illustrate, in the example below, VPE completes nearly all the manufacturing steps without the need to outsource:

- Design – VPE’s engineers work closely with the customer through multiple revisions until they achieve the optimal design.

- Component machining – VPE’s machine shop precision machines the component parts such as tops, middles, and bottom plates.

- CMM Inspection – if necessary and after machining, the quality assurance department thoroughly inspects the components on CMM machines for conformance.

- Cleaning & assembly – technicians clean and assemble the components to prepare for vacuum brazing or diffusion bonding.

- Vacuum brazing or diffusion bonding – technicians load the assembly into a vacuum furnace or diffusion bonder and run the assembly at a specific temperature as well as force profile.

- Leak Testing – after brazing or bonding, technicians perform leak checking to verify a perfect join.

- Heat Treating – after leak checking, the assembly goes to heat treating in-house or sent outside if it requires certain specifications.

- Final Machining – after heat treating, the machine shop machines the assembly into its final shape.

- CMM Inspection – if necessary and after machining, the quality assurance department thoroughly inspects the assembly on CMM machines for conformance.

- Coating and/or Plating – coating and/or plating is done outside of VPE and the final part is sent to a reliable coating supplier to perform services such as chemical film coating or gold plating.

- Final Assembly – technicians install the final components such as heli-coils into the final part.

- Final Testing – technicians perform bubble and/or leak testing to verify the final part is leak proof.

- Last Inspection – the quality assurance department inspects as well as certifies the final part.