Performance properties not available from a single metal.

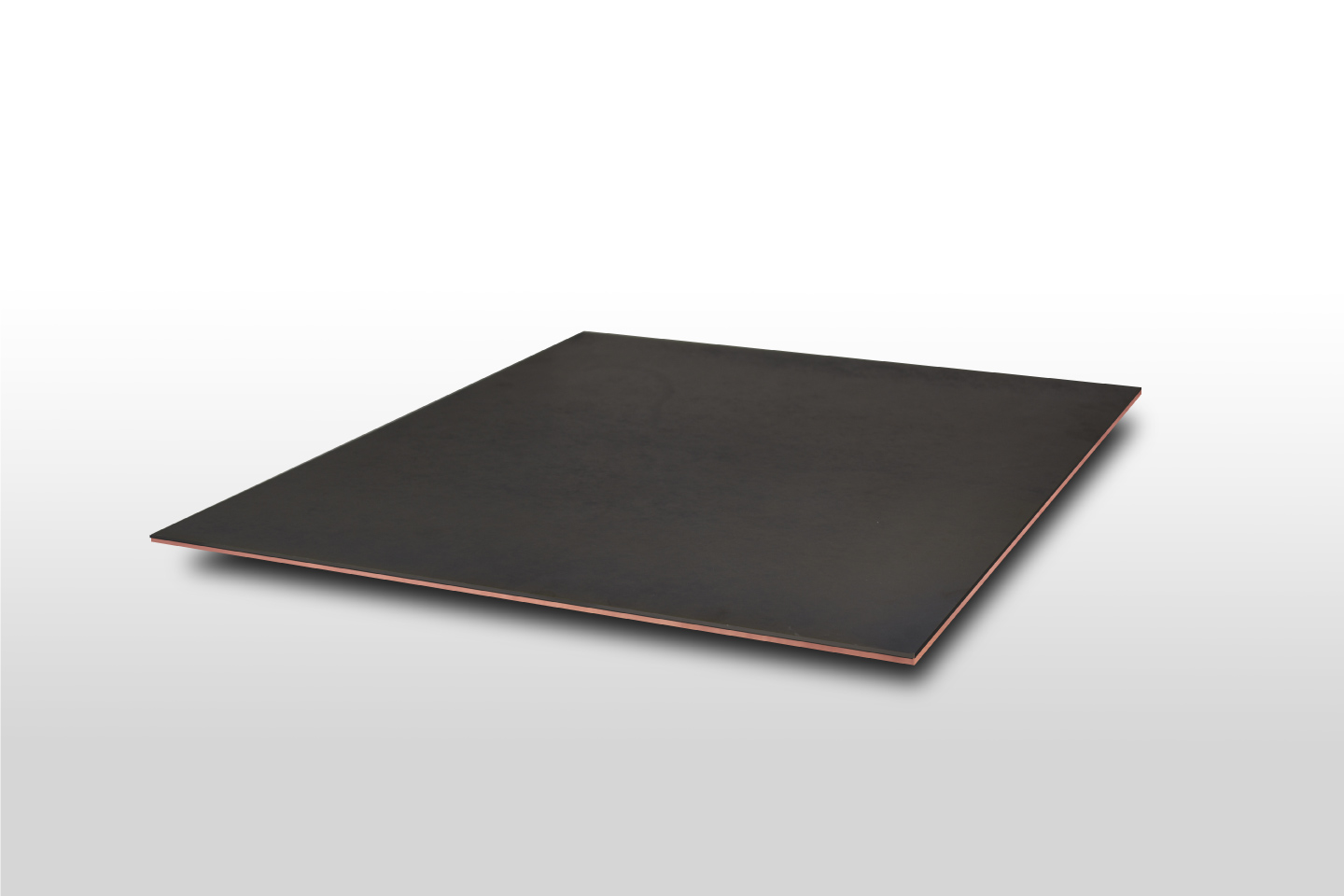

VPE utilizes diffusion bonding as well as other methods to manufacture laminated & clad metal sheet. As a result, the sheet is bonded at the atomic level. Furthermore, it comes in a wide range of alloys as well as configurations.

Moreover, laminated & clad metal sheet provides a means of creating a composite material with performance properties not available from a single metal. In addition, sheet properties may be tailored to a particular application, e.g. bending strength, thermal as well as electric conductivity, reduced porosity, as well as corrosion resistance.

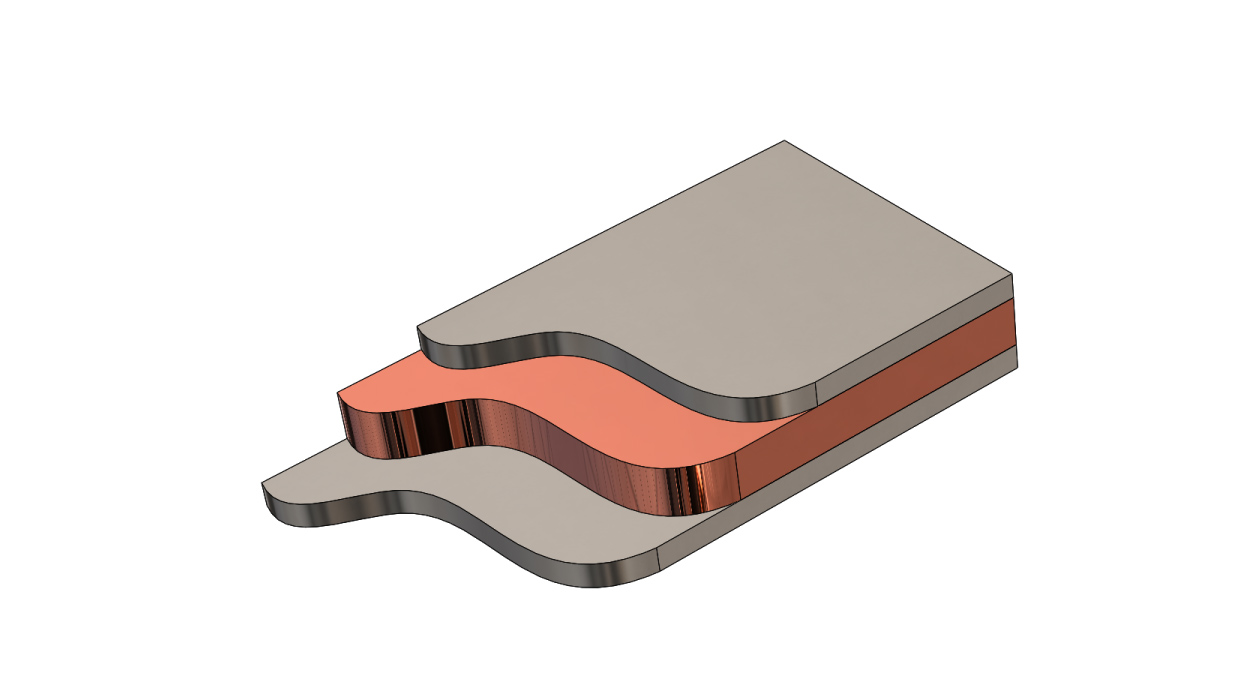

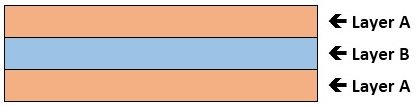

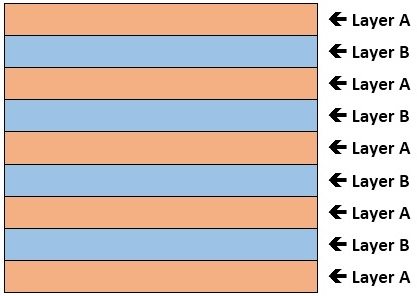

The sheet is routinely in a tri-layer configuration. However, also available are bi-layer as well as multiple repeating layer fabrications.

Bi-Layer

Tri-Layer

Repeating Layer

Materials bonded e.g.:

- Aluminum

- Bimetallic (dissimilar metals)

- Carbon Steel

- Composites

- Copper

- Nickel-based Alloys

- Precious Metals

- Refractory Metals

- Stainless Steel

- Titanium

The surfaces are generally provided in an as-bonded condition. However, the surfaces may optionally be finished with various coatings e.g.:

- Dark chrome oxide (for stainless steels)

- Nickel plating

- Copper plating

- Polished

- Blasted

VPE’s variety of diffusion bonding furnaces allow for various sizes of sheet e.g.:

- Sheet sizes to 1.5 meters x 3 meters

- Sheet thicknesses from less than 0.0004 in. to greater than 5 in.

- Assembly weights to 60,000 lbs.

If necessary, internal features can be preserved inside the bonded part e.g.:

- Heating elements

- Fluidic channels

A wide variety of industries e.g.:

- Power generation

- Solar energy

- Thermal transfer

- Oil & Gas

- Chemical processing

- Cryogenic/refrigeration

- Semiconductor

- Space

- Marine

- Electrical

- Structural

- Transportation

- Aluminum smelting

- Desalinization

- Food processing

- Paper as well as Pulp

- Cutlery

- Jewelry

Many applications e.g.:

- Weld transitions

- Corrosion resistance, e.g. chemical processing

- Corrosion resistance, e.g. galvanic

- Maintain electrical connections

- Reduce oxidation as well as connectivity concerns

- Reduce structural weight

- Maintain strength at high temperatures

- Lower the porosity of the metal(s)

- Solar cell cooling

- Cold plates, as well as panels, cooling

- Particulate matter cooling as well as heating

- Isothermal panels

- Sputtering targets

- Heat pipes

- Heat exchangers

- Clad knives

- Makume-gane jewelry

| Part Number | Type | Sheet Size (W x L x H) (in) | Face Layer Material Thickness (in) | Core Layer Material Thickness (in) | Face Layer Finish |

|---|---|---|---|---|---|

| CL-01001 | Tri-Layer | 17.5 x 21 x 0.090 | 316/316L (0.015) | CDA 101 Copper (0.070) | Dark Chrome Oxide |

| CL-01002 | Tri-Layer | 17.5 x 21 x 0.090 | 316/316L (0.015) | CDA 101 Copper (0.070) | Nickel Plated |

| CL-01003 | Tri-Layer | 17.5 x 21 x 0.090 | 316/316L (0.015) | CDA 101 Copper (0.070) | As-Bonded |

Please send your requirements as well as print to info@vpei.com. As a result, an engineer will respond to help determine the best design for your application.