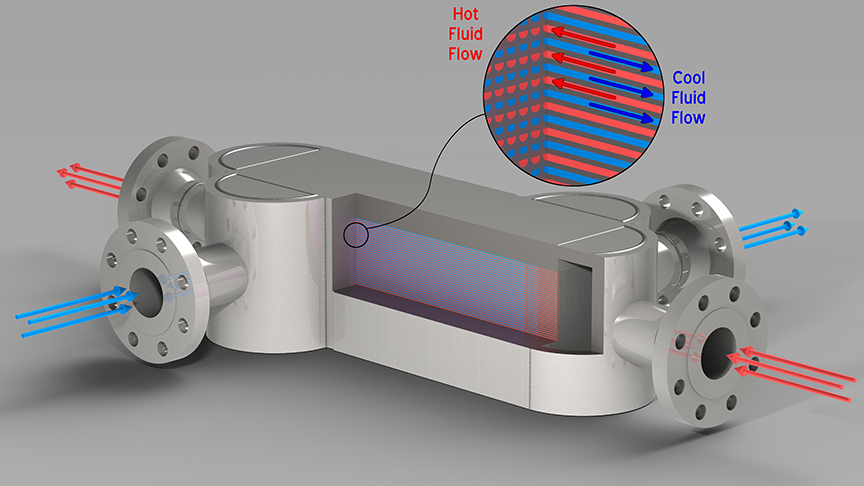

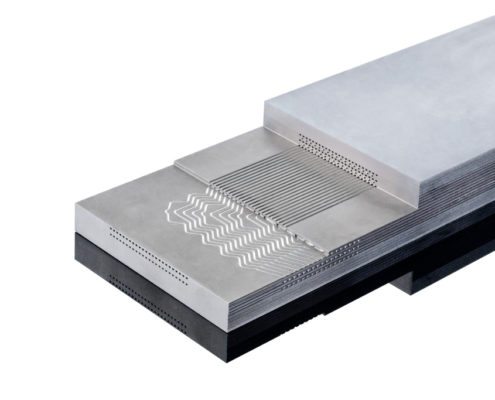

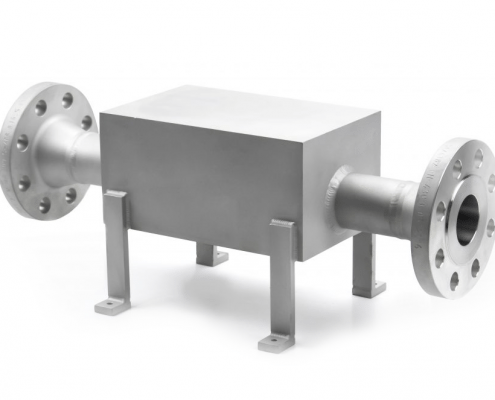

VPE Thermal LLC, a subsidiary of VPE, manufactures custom diffusion bonded microchannel heat exchangers (MCHEs), also known as printed circuit heat exchangers (PCHEs), for a diverse range of industries. Furthermore, these compact heat exchangers are ideally suited for high-pressure and high-temperature applications.

Inside a Diffusion Bonded Microchannel Heat Exchanger

A general overview of fabricating a diffusion bonded microchannel heat exchanger, also known as a printed circuit heat exchanger:

- The VPE THERMAL® engineering team calculates the design needed to meet the requirements of the heat exchanger.

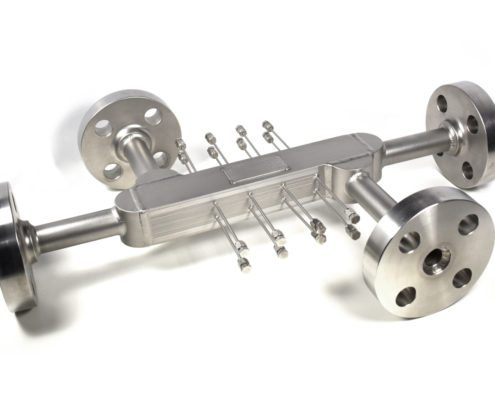

- An outside manufacturer etches plates or shims with the flow design.

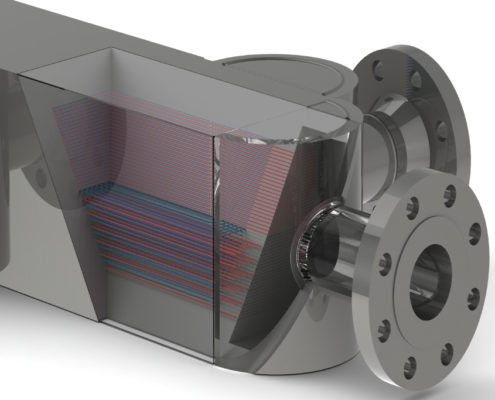

- Technicians assemble the shims in a counter-flow configuration.

- The stacked plates are diffusion bonded to create a solid heat exchanger core without gaskets. Perfected since 1976, VPE’s proven diffusion bonding process ensures parent material strength throughout the core of the heat exchanger.

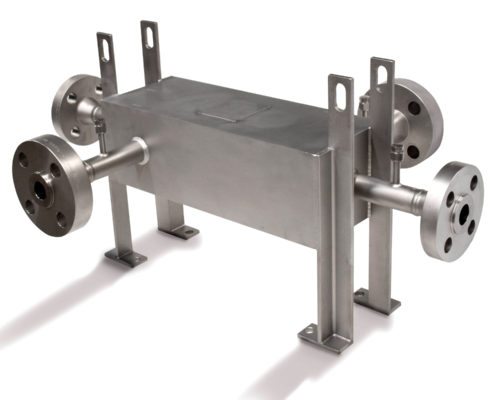

- The diffusion bonded core is machined to size at VPE’s machine shop.

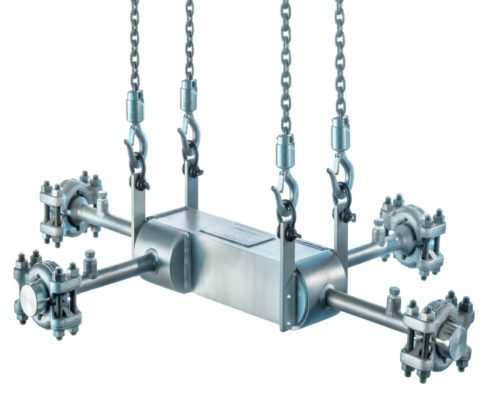

- The welding team joins the required manifolds, flanges, and components to the core of the heat exchanger.

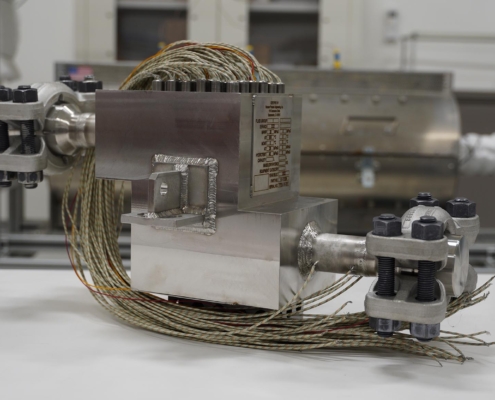

- A Technician carefully cleans and tests the heat exchanger to verify it is leak-proof.

- VPE THERMAL® diffusion bonded microchannel heat exchangers are “U” or “UM” stamped and meet the requirements of the ASME Boiler and Pressure Vessel Code.

Advantages of Diffusion Bonded Microchannel Heat Exchangers

There are many advantages of diffusion bonded microchannel heat exchangers (MCHEs) e.g.:

- The heat exchanger core is diffusion bonded to create a solid core without gaskets, interlayers, or brazing.

- The core design handles the maximum design pressures of the two streams at the highest temperature. As a result, there is enhanced safety.

- Incredibly resistant to vibrations and catastrophic failure modes.

- Highly compact construction for the productive use of small spaces relative to other configurations.

- MCHEs are resistant to freezing

- Savings through low weight and fluid inventory.

- Close approach temperatures in a counter-flow configuration.

- High-efficiency heat exchange design, which incorporates the characteristics of microchannels and diffusion bonding manufacturing.

- Corrosion-resistant alloys are used for compatibility with a wide range of process streams.

- Multi-stream capability in a single device.

A Wide Range of Industries

Industries for diffusion bonded microchannel heat exchangers e.g.:

- Renewable power: solar, geothermal, as well as wind (generator cooling)

- Brayton cycle utilizing supercritical CO2

- Organic Rankine Cycle (ORC)

- Chemical production: ethylene, nitric acid, methanol, as well as propylene

- Synthetic fuels as well as biodiesel

- Gas generation: hydrogen as well as PSA nitrogen

- Combined heat and power (CHP)

- Onshore as well as offshore oil & gas

- Pharmaceutical

- Waste heat recuperation

- Cryogenic temperatures

- Botanical extraction

Solutions for Challenging Applications

There are many applications of custom-designed diffusion bonded microchannel heat exchangers e.g.:

- LNG recovery

- LNG superheaters

- Floating LNG exchangers

- LNG chillers and pre-coolers

- LNG liquification

- Fuel gas performance heaters

- LNG regasifier

- Fuel gas preheaters

- Fuel gas superheaters

- Gas compressor coolers

- Fuel cell chillers or pre-coolers

- Freeze resistant/protection applications

- Compressor discharge coolers

- Micro gas turbine recuperators

- Turbine regenerators

- Regasification

- Steam generators

- Kettle reboilers

- Waste heat recovery unit (WHRU)

- Feed water heaters

- Air pre-heaters

- Inlet coolers and chillers

- Compressor intercoolers

- Compressor aftercoolers

- Hydrogen chillers and pre-coolers

- CO2 chillers and coolers

- Rotary air coolers

- Lube oil coolers

- Quench coolers

- After chillers and aftercoolers

- Dew point control

- Recuperators

- Regenerators

- Economizers

- Condensers

- Supercritical CO2 recuperators

- Botanical extraction applications

Custom Designed Diffusion Bonded Microchannel Heat Exchangers

Many customers require a custom-designed heat exchanger to meet their unique requirements. Accordingly, we are experts at custom heat exchangers. Therefore, we design and manufactures heat exchangers in all shapes and sizes to maximize performance and minimize cost. Furthermore, we can develop a unit to your exact specifications or design a custom system that achieves your desired performance requirements.

For a quote, please submit your requirements through our heat exchanger quote form below. If you need more information and help from our thermal engineering team before you can complete the form, please email info@vpei.com.

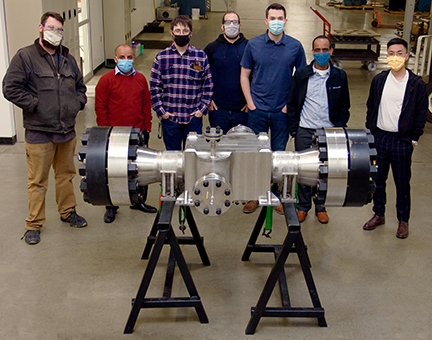

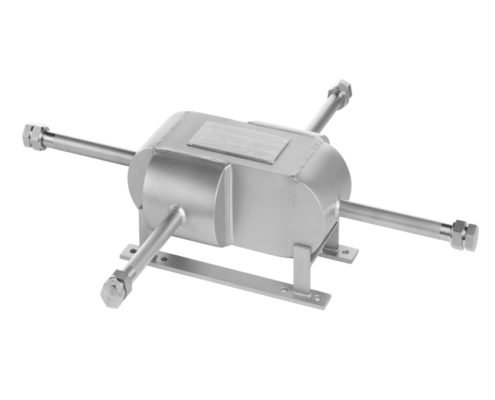

Hydrogen Pre-Cooling Heat Exchangers (H2PC®)

A popular application for diffusion bonded microchannel heat exchangers is hydrogen pre-cooling heat exchangers H2PC®. Thus, we offer various sizes of H2PC® and hydrogen recuperators for different hydrogen fill rates.

We manufacture H2PC® for use in hydrogen fueling stations that can handle pressures at 1000+ barg. In addition, H2PC® address operational and cost targets established by the department of energy (DOE).

H2PC® realize many advantages for hydrogen pre-cooling, including the B2B fill capability is virtually infinite and there are significant savings with low weight and fluid inventory. As a result, they can fit in a small footprint such as a dispenser cabinet.

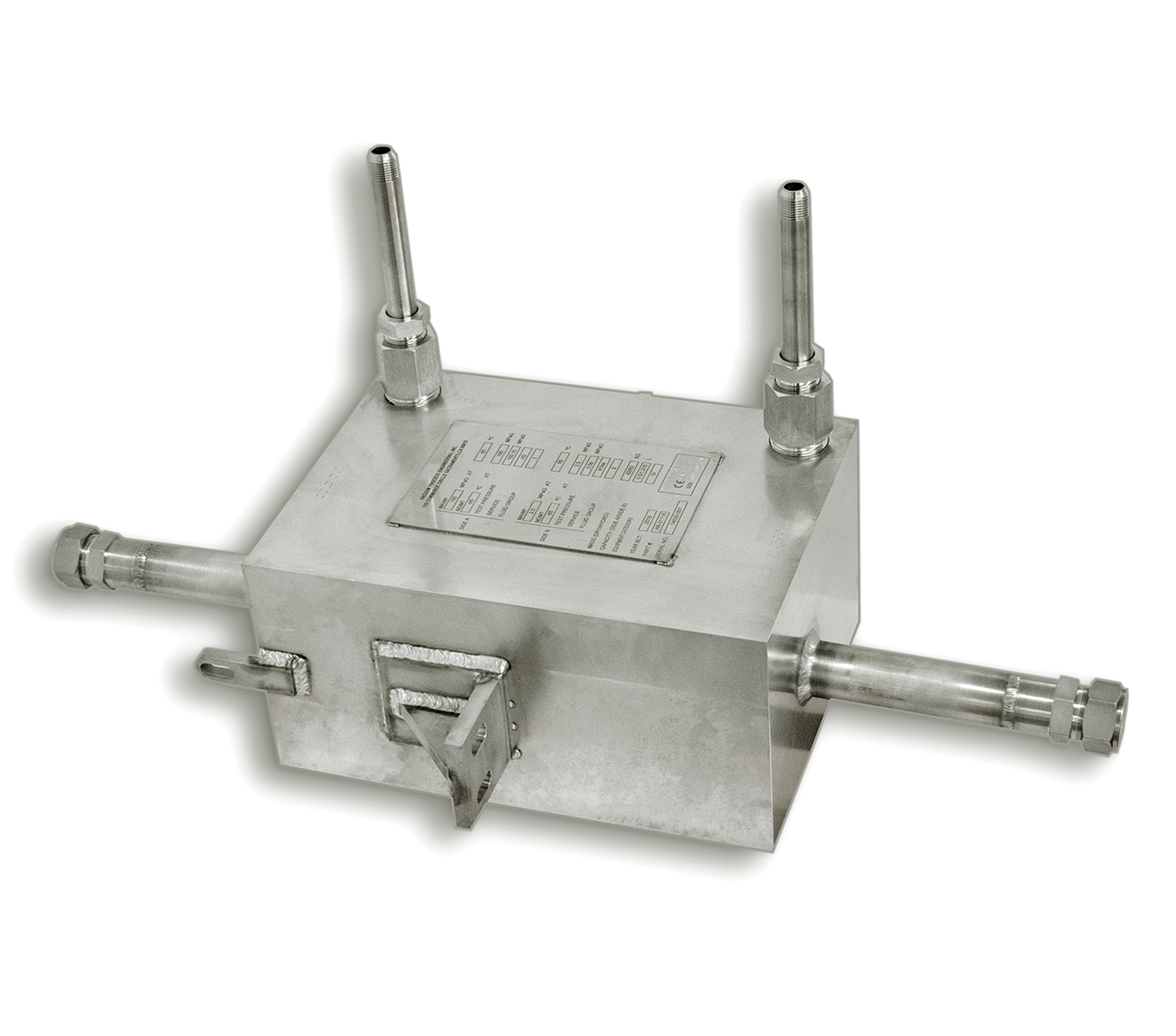

Commercial Off-The-Shelf Heat Exchangers

We fabricate much smaller, compact sizes of the diffusion bonded microchannel heat exchangers as well. Therefore, we offer these high-reliability, compact heat exchangers in custom and commercial off-the-shelf models.

Just some of the applications for these smaller heat exchangers e.g.:

- Precise temperature control

- Processing equipment

- Cooling and heating of fluids as well as gases

- Botanical extraction applications

Equipment & Facilities for Heat Exchangers

At VPE, the parent company of VPE THERMAL®, there are over 150,000 square feet of design, lab, production, and quality assurance space. Presently, heat exchanger manufacturing uses these facilities and equipment e.g.:

- Vacuum brazing furnaces

- Aluminum vacuum brazing furnaces

- Diffusion bonding furnaces

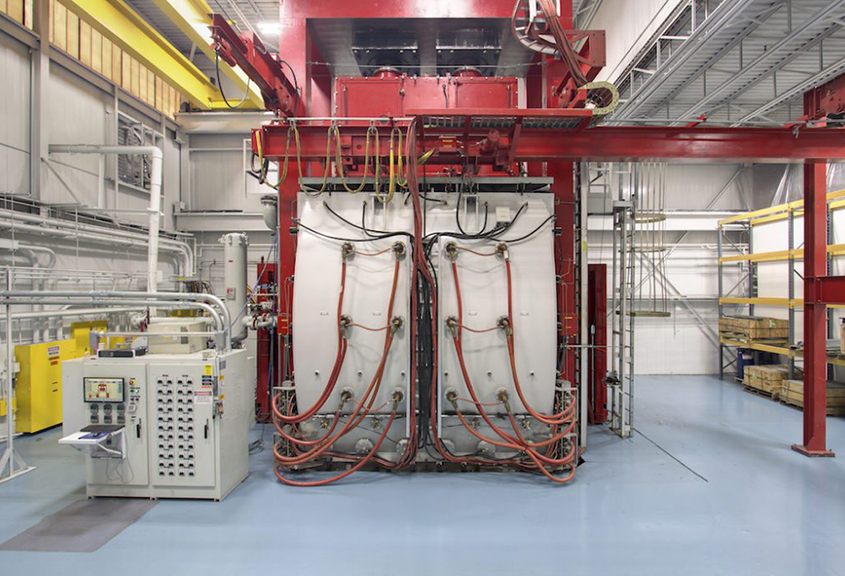

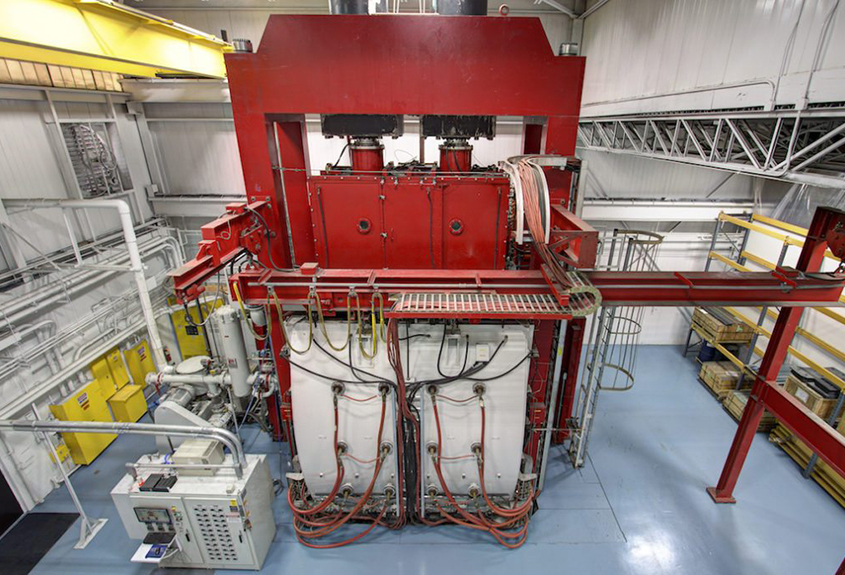

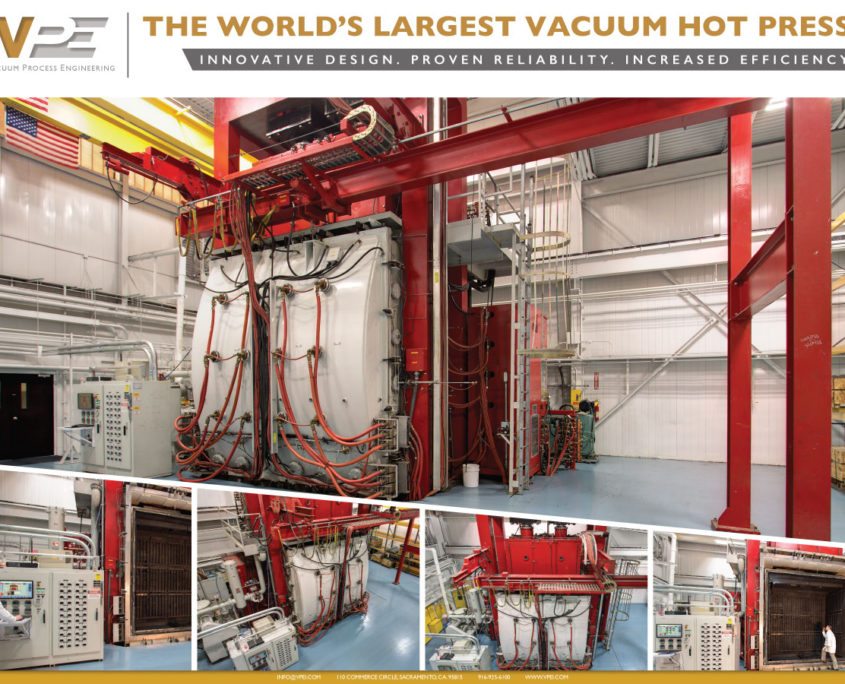

- The world’s largest vacuum hot press

- Machine shop

- Quality assurance facility

- Welding cells

- Cleaning lines

- Assembly lines

VPE, the parent company of VPE THERMAL®, currently owns the world’s largest vacuum hot press furnace. As a result, VPE THERMAL® is perfectly suited for bonding large-sized heat exchanger cores, or multiple cores at once.

- The usable chamber area is 60 in. x 120 in. x 120 in.

- Temperatures in excess of 1900° Celsius in a vacuum and partial pressure atmosphere.

- Two independent 1200 ton rams allow for loads to 4.8 million pounds.

- Ten high accuracy load cells allow precision force as well as precision control on the production elements.

- Assembly weights in excess of 60,000 lbs.

Advantages of Working With VPE

VPE, the parent company of VPE THERMAL®, is providing the metallurgical services, engineering, and contract manufacturing expertise our customers require to meet their demanding performance, cost, and lead-time goals. Simultaneously, we work closely with OEMs, suppliers, and technology integrators to create the most efficient and effective diffusion bonded microchannel heat exchangers.

- Over 45 years of diffusion bonding experience.

- Design and manufacturing with engineering assistance.

- A tested and proven manufacturing process.

- A redundant and burst capacity facility for fast turn and reliable sourcing.

- State-of-the-art technical facilities.

- A large-assembly diffusion bonding experience and facility.

- A developed supply chain.

Quality Assurance Certifications & Registrations

VPE THERMAL® commits to meeting customer quality and on-time delivery expectations through practicing continuous improvement and by operating an effective quality management system compliant to ISO & ASME.