Utilizing hydrogen, vacuum, argon, air, and controlled dew point furnaces, VPE provides a variety of heat treating services and other specialty thermal processes for standard and custom products. In addition, we have extensive experience processing materials for laser, UHV, spectrometer, particle physics apparatus, space hardware, as well as other critical devices.

Heat Treating Capabilities

Capabilities e.g.:

- Assembly weights in excess of 60,000 pounds

- Assembly sizes up to 60 inches in diameter and 120 inches in length

- Temperatures to 2000°C

- Vacuum baking to national laboratory standards

- Laser component pulse purge processing

- Precise dew point control processes for surface enhancement

- Hydrogen annealing

Vacuum Baking

We routinely perform out-gassing by thermal processing (vacuum baking) of space hardware, seals, novel materials, and assemblies to specification for major aerospace contractors and electronics producers.

Controlled Dew Point Processing

Controlled dew point processing enables VPE to oxidize and treat product selectively for specialized applications.

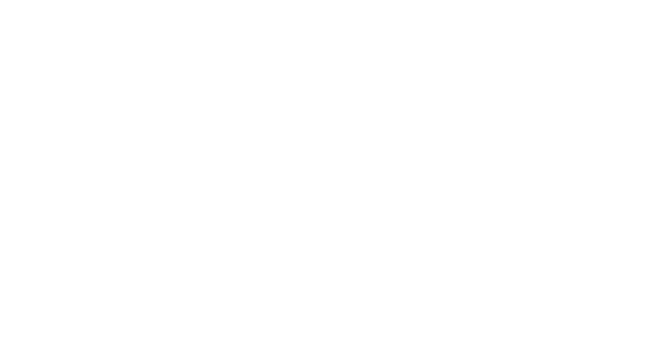

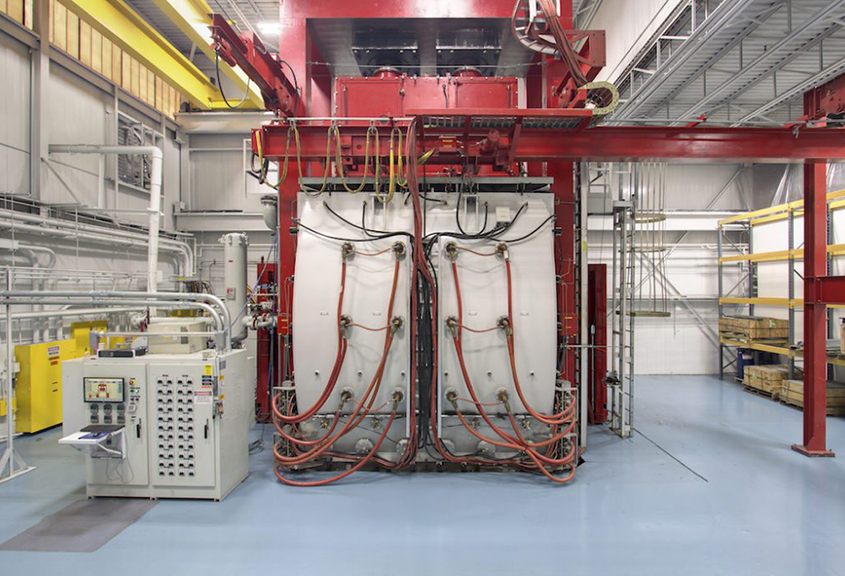

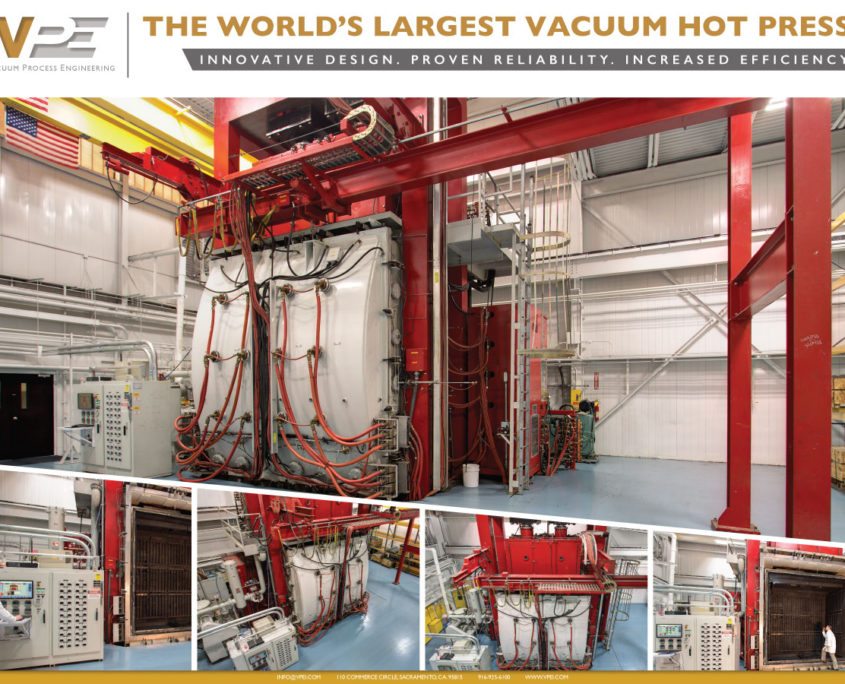

The World’s Largest Vacuum Hot Press

VPE currently owns the world’s largest vacuum hot press furnace. As a result, VPE is perfectly suited for brazing, bonding, hot pressing, and heat treating large size assemblies or batches.

- The usable chamber area is 60 in. x 120 in. x 120 in.

- Temperatures in excess of 1900° Celsius in a vacuum and partial pressure atmosphere.

- Two independent 1200 ton rams allow for loads to 4.8 million pounds.

- Ten high accuracy load cells allow precision force as well as precision control on the production elements.

- Assembly weights in excess of 60,000 lbs.