VPE’s machine shop continues to increase its capabilities. In addition, we provide complex and precision parts for many industries including aerospace, commercial, medical, as well as the Department of Defense. Furthermore, the machine shop excels at intricate and tight tolerance processes using three, four, as well as five-axis CNC milling and turning equipment. Moreover, VPE is now able to incorporate most (if not all) the manufacturing processes in-house. As a result, this gives VPE and its customers a major advantage as the projects are more efficiently managed.

Machined Alloys

VPE has machined the following alloys e.g.:

- Aluminum

- Stainless steel

- Copper

- Titanium

- Plastics as well as Polymers

- Exotic alloys

- Nickel-based alloys including Inconel as well as Haynes

- Refractory metals

Major Customers

A small selection of customers the VPE machine shop has worked with e.g.:

- Raytheon

- Lockheed Martin

- L3Harris

- Northrop Grumman

- Applied Materials

Machine Shop Equipment List

| NAME | MODEL | TRAVEL SIZE (IN.) |

|---|---|---|

| Haas Vertical Machining Center | VF-2SSYT | 30 x 20 x 20 |

| Haas Vertical Machining Center | VF-4SS | 50 x 20 x 25 |

| Haas Vertical Machining Center | VF-4SS | 50 x 20 x 25 |

| Haas Vertical Machining Center | VF-6SS | 64 x 32 x 30 |

| Haas Vertical Machining Center | VF-6SS | 64 x 32 x 30 |

| Haas Vertical Machining Center | VF-6SS | 64 x 32 x 30 |

| Haas Vertical Machining Center | VF-6SS (with Pallet Loader) | 64 x 32 x 30 |

| Haas Vertical Machining Center | VF-11/40 | 120 x 40 x 30 |

| Haas 5-axis Machining Center | UMC-750SS | 30 x 20 x 20 |

| Matsuura 5-axis Machining Center | MX-520 | 25 x 22 x 20 |

| Haas Horizontal Machining Center | EC-400 | 22 x 25 x 22 |

| Haas Turning Center | ST-30Y | 9.4 x 2 x 32.5 |

| Mitsubishi Wire Cut System | BA24 | 24 x 16 x 13 |

| Coordinate Measuring Machine | Coord3 Universal 15.13 | 118 x 59 x 51 |

| Coordinate Measuring Machine | Coord3 Ares NT 12.07.07 | 47 x 26 x 26 |

Machine Shop Quality Assurance with CMM Inspection

VPE’s large-scale Coordinate-Measuring Machines (CMMs) verify the machined parts meet their design specifications. Furthermore, customers require tight tolerances and CMM inspection gives the measurement needed to pass or fail the part.

- Large-scale CMMs to verify the conformance of precise parts

- Coord3 Universal

- Travel Size: 118 in. x 59 in. x 58 in.

- Coord3 Ares NT

- Travel Size: 47 in. x 26 in. x 26 in.

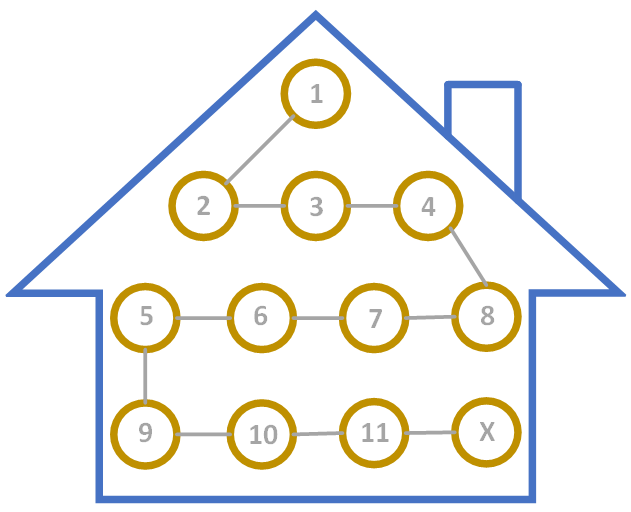

In-House Manufacturing: From Start to Finish

Extensive manufacturing capabilities allow the VPE manufacturing process to be done nearly entirely in-house. To illustrate below, VPE completes nearly all the manufacturing steps without the need to outsource:

- Design – VPE’s engineers work closely with the customer through multiple revisions until they achieve the optimal design.

- Component machining – VPE’s machine shop precision machines the component parts such as tops, middles, as well as bottom plates.

- CMM Inspection – after machining, the quality assurance department thoroughly inspects the components on CMM machines for conformance.

- Cleaning & assembly – technicians clean as well as assemble the components to prepare for vacuum brazing or diffusion bonding.

- Vacuum brazing or diffusion bonding – technicians load the assembly into a vacuum furnace or diffusion bonder and run the assembly at a specific temperature as well as force profile.

- Leak Testing – technicians perform leak checking to verify a perfect join.

- Heat Treating – the assembly goes to heat treating in-house or sent outside if it requires certain specifications.

- Final Machining – the machine shop machines the assembly into its final shape.

- CMM Inspection – if necessary and after machining, the quality assurance department thoroughly inspects the assembly on CMM machines for conformance.

- Coating and/or Plating – coating and/or plating is done outside of VPE and the final part is sent to a reliable coating supplier to perform services such as chemical film coating or gold plating.

- Final Assembly – technicians install the final components such as heli-coils into the final part.

- Final Testing – technicians perform bubble and/or leak testing to verify the final part is leak proof.

- Last Inspection – the quality assurance department inspects as well as certifies the final part.