Precision brazing since 1976.

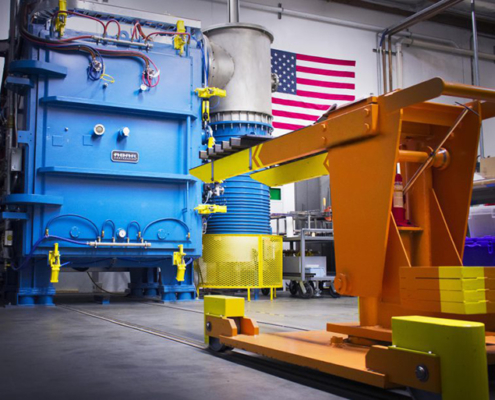

Successful precision brazing can result in lower production costs as well as higher production yields. In addition, it can result in more robust end-use performance. For this reason, VPE has been developing and optimizing our precision brazing services since 1976. Furthermore, by combining materials science awareness with extensive experience, we are able to control the myriad of details that are critical for successful brazing.

Precision Brazing Processes

VPE is capable of many different types of precision brazing e.g.:

- Vacuum Brazing

- Aluminum Vacuum Brazing

- Hydrogen Furnace Brazing

- Induction Brazing

- Infrared (Quartz Lamp) Brazing

- Diffusion

- Inert Gas

- Laser & torch

- Pressure assisted (applied force)

- Retort

- Controlled atmosphere

- Ultra-fast

- Controlled dew point

- Joint design to meet service requirements

Considerations

Assembly Features

With increasing frequency and if we apply conventional design criteria, there are instances where assembly features constrain the design of a braze joint and render the assembly “not brazeable”.

Factors that drive these assembly features e.g.:

- Component geometries that are becoming much smaller

- Materials innovations

- Market competitiveness

- New machining innovations

Capillary Action

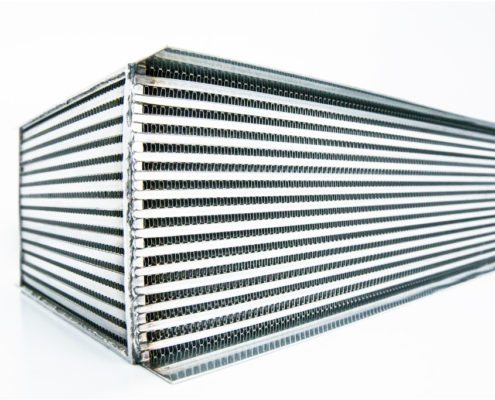

A key factor in precision brazing is capillary action, which ensures proper filler metal distribution. Furthermore, it is of particular importance when brazing assemblies that incorporate microchannels and other small features.

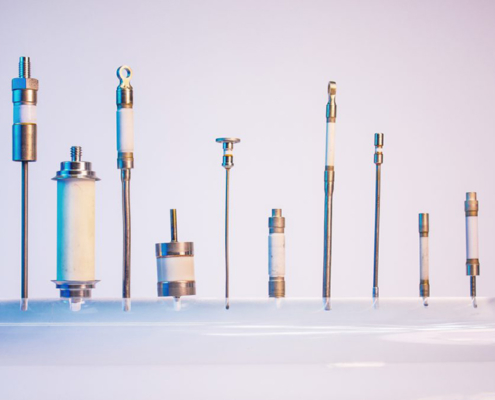

Biocompatible Materials for Medical Applications

Thin film metalized ceramics for miniature feedthroughs used in medical devices require the use of specific biocompatible materials. However, yesterday’s materials choices are not acceptable in these applications. To clarify, biomaterials are often reactive and limiting; accurately controlling the time-at-temperature makes some designs suitable that would otherwise not work.

Filler Alloy Type

Conventional brazing uses “in-stock” or “inventoried off-the-shelf” forms of filler alloy for the sake of convenience. Conversely, in precision brazing, we select or develop the alloy chemistry appropriate for the application to meet the strength as well as the environmental/service requirements.

Filler Alloy Quantity

In precision brazing, serious consideration is given to determining how much filler alloy to use for a given assembly. In addition, precision brazing challenges the old rule of thumb of using 125% to 150% of joint volume as the amount of filler alloy to employ.

Filler Alloy Metallurgy as well as Metallurgical Reactions

Filler alloys may react to form lower-melting eutectics with consequences that are often difficult to predict. However, when performing precision brazing services, we frequently make use of metallurgical reactions to obtain optimal brazing results.

Critical Process Parameters

Applied Force

We can reduce the uncertainty of whether the mating surfaces predictably seat against one another by applying a force during precision brazing. For this purpose, the use of a deadweight, hydrostatic pressure, differential thermal expansion effects, or an active force from a hydraulic ram applies the force.

Diffusion Brazing and Transient Liquid Phase Diffusion Bonding

These processes can provide a brief period of liquid at the joint interface, helping to achieve intimate contact. Furthermore, the liquid will solidify isothermally under correct processing to achieve high-strength bonds.

Filler Alloy Application Technique

EDM methods precision-fabricate preforms to achieve precise placement of the filler alloy. Furthermore, the preforms help keep the filler alloy away from capillaries. Applying preforms e.g.:

- Foil, wire, and powder—by hand, pneumatic, or robotic techniques

- Wet plating

- PVD coatings

Filler Alloy Flow-Arresting Features

To clarify, we use channels (or even sharp corners) to impede the flow of filler alloy.

Joint Design—Volume, Volume Control, as well as Assembly Fit-Up

Knowing the joint volume is important in determining the amount of filler alloy to use. In addition, our design engineers review assembly tolerances to assure the assembly performs work in service as well as use an optimal amount of brazing filler metal.

Rapid Brazing

To clarify, rapid brazing processes avoid undesirable brittle inter-metallic reactions.

Time-Temperature-Applied Force Profile

With a time-temperature-applied force profile, fundamental parameters have the capacity to alter metallurgical reactions. Hence, VPE considers the role of each parameter carefully when designing critical assemblies.

Other Important Process Parameters

Important process parameters e.g.:

- Interface chemistry

- Production tooling design

- Selective enabling or limiting capillary action

- Service environment e.g.: hermeticity, corrosive, temperature, stress, life, creep, as well as fatigue

- Temperature profile design

Parent Materials Brazed

Experience with many types of materials e.g.:

- Aluminum

- Aluminum nitride

- Brass

- Aluminum oxide

- Ceramics

- Composites

- Copper

- Glidcop™

- Havar™

- Haynes

- Inconel™

- Invar™

- Kovar™

- Molybdenum

- Nickel

- Platinum

- Reactive materials

- Rhenium

- Silver

- Stainless steel

- Tantalum

- Titanium

- Tungsten

- Tungsten carbide

- Vanadium

Examples of Precision Brazing Applications

Experience with many types of parts e.g.:

- Aerojet Rocketdyne: satellite thruster nozzles

- Fortune 10 corporation: reactor and gas turbine components

- Major aerospace contractor: engine fire sensors

- Major medical device corporation: ceramic-to-metal heater assemblies

- NASA: Space Exploration as well as Lander Programs

- Major medical and industrial corporation: ceramic to metal electrical seals

- Microchannel devices

- Detectors

- Cathodes

- Cold Plates as well as Cold Walls

- Biomedical Assemblies

- Microwave Devices

- Electron Accelerators

- Cyclotrons