Vacuum brazing is a precision brazing technique used to join critical assemblies, many of which employ delicate or intricate features. For this reason, extensive experience in materials joining enables VPE to customize and ensure the best process conditions for your assembly application.

The Vacuum Brazing Process

Clean Process Ensures Contaminant-Free Brazes

Vacuum Brazing employs vacuum as an ambient atmosphere so components undergoing the brazing process will not react with excessive oxygen, moisture, nitrogen, or other gaseous contaminants. In addition, by limiting the reactions with the surrounding atmosphere, we can create a clean environment that is conducive to filler alloy wetting and flow onto metal surfaces as well as into capillary joints.

Furthermore, the vacuum environment can also reduce surface contamination from oxides and other compounds through the sublimation of the species due to chemical reduction. To clarify, the maintenance of a clean environment is essential to the production of contaminant-free brazes. Hence, VPE often utilizes cryogenic or turbomolecular pumping to assure the brazing environment is free of excessive hydrocarbons from the vacuum pumping system.

Pre-Placement Helps Create the Strongest Possible Bond

VPE pre-places the filler alloy on the assembly in such a location that as the furnace temperature raises and the filler metal alloy melts, it also flows into the assembly capillary joints and affects a good bond.

Precise Vacuum Level Parameters Assure Quality Brazing

Typical vacuum levels achieve 1E-5 to 1E-6 Torr during brazing, and much higher vacuums are used in several other reactive metal applications. Furthermore, in some applications, the partial pressure of inert gas is used to mitigate the volatilization of filler metals or parent materials. These partial pressures range from about 1 to 10 Torr.

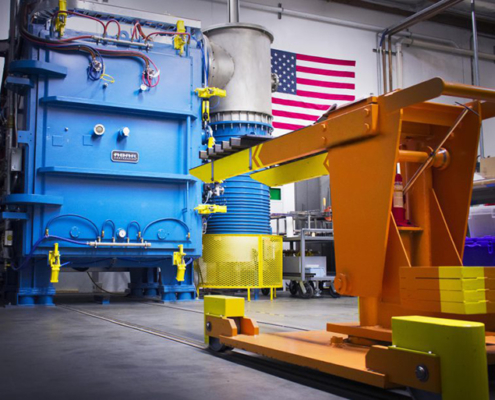

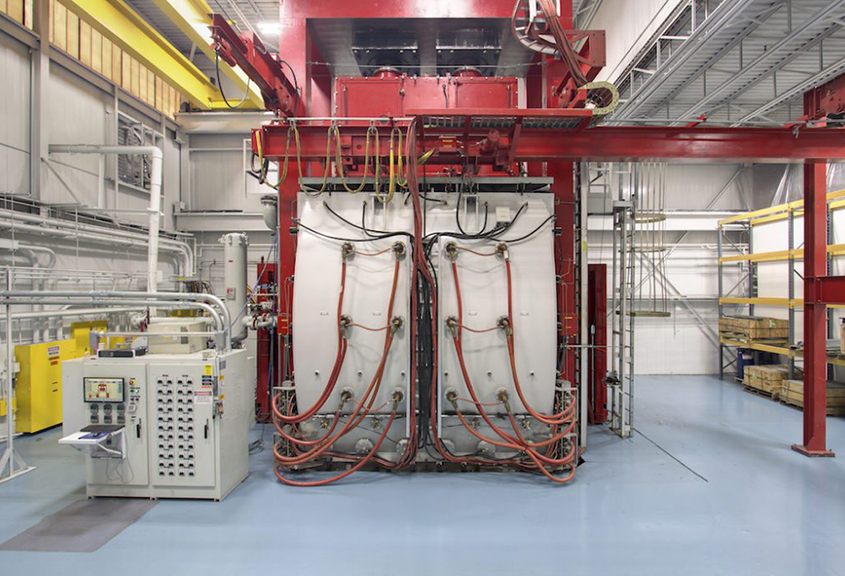

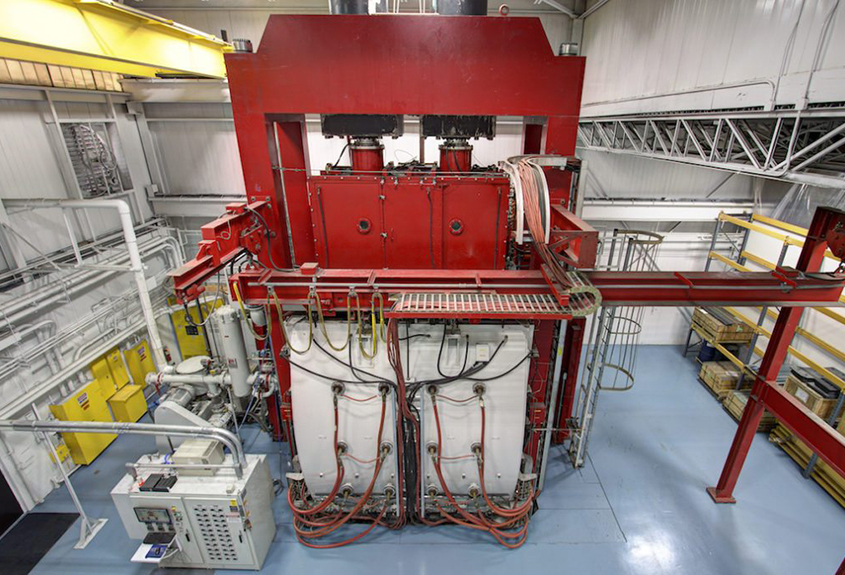

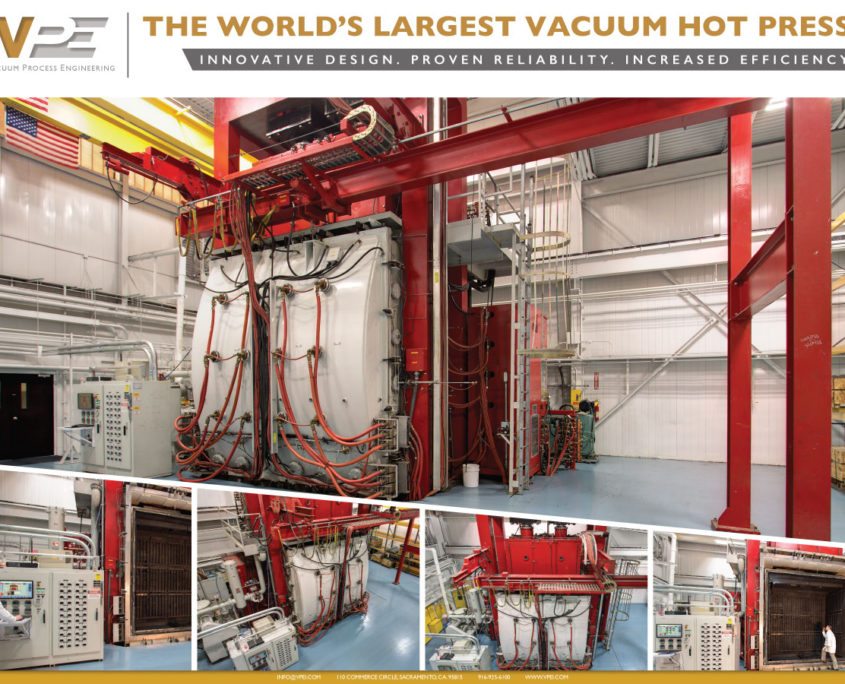

Capabilities & The World’s Largest Vacuum Hot Press

VPE owns vacuum furnaces for vacuum, partial pressure, hydrogen, and argon atmospheres which provide a clean environment where components will not react with oxygen, moisture, nitrogen, or other gaseous contaminants.

In addition, VPE currently owns the world’s largest vacuum hot press furnace, which is perfectly suited for brazing, diffusion bonding, and hot pressing!

Capabilities e.g.:

- Reactive materials brazing

- Active metal brazing of ceramics

- Assembly weights in excess of 60,000 pounds

- Product size to 120 in. x 120 in. x 60 in.

- Temperatures range to 1900°C in a vacuum and partial pressure atmosphere.

Applications

A diverse array of applications e.g.:

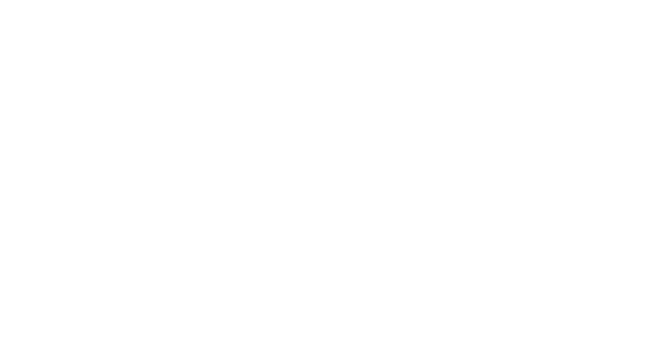

- Sensors

- Detectors

- Cathodes

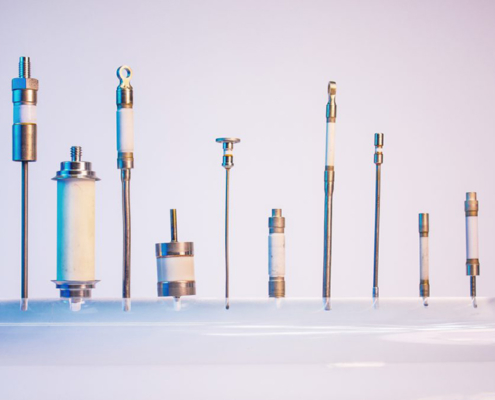

- Cold plates

- Cold Walls

- Heat exchangers

- Radiators

- Biomedical assemblies

Materials Joined

Materials joined e.g.:

- Titanium

- Copper

- Stainless Steel

- Ceramics

- Aluminum

- Steel

- Tungsten carbide

- Tungsten